During a time of economic turmoil, tariff-related uncertainty and rising supply-chain anxiety, some integrators are positively differentiating themselves with their mindful approach to the global supply chain. AVI-SPL is certainly one of those, boasting a fast-growing Global Supply Chain team of 100-plus associates.

In this exclusive interview with Jeremy Codiroli, Vice President, Global Supply Chain, AVI-SPL, Commercial Integrator offers a glimpse at the secret sauce that’s helping the global integration leader not merely grapple with ongoing change but, indeed, leverage real‑time data and rigorous analysis to enjoy success. Ultimately, Codiroli says, AVI-SPL’s approach uniquely positions the team in a world in which macroeconomic variables are quickly being added, adjusted and upended.

Commercial Integrator: For those who might not be familiar with the AVI-SPL Global Supply Chain team, can you give us a 30,000-foot overview of what you do and how you do it?

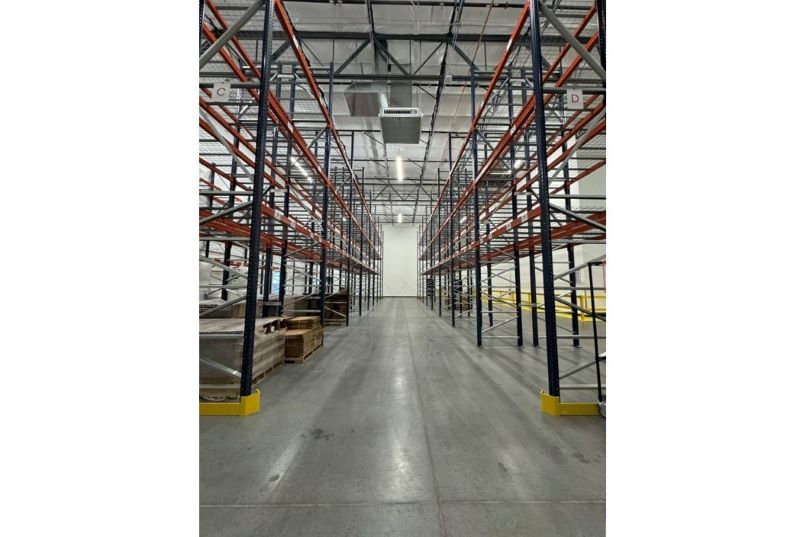

Jeremy Codiroli: Our team comprises a globally diverse group of experts in logistics, warehousing, inventory, fleet and international trade — all unified by a single goal: running the most elite supply chain in the industry. We want our customers feel an undeniably elevated experience driven by our Global Supply Chain team’s authentic “customer-centric” approach.

CI: The AVI-SPL Global Supply Chain team now has over 100 people across the world as part of it. Contextualize the explosive growth that the team has experienced in just two years. What has powered it?

Codiroli: Results and customer feedback. AVI-SPL made the decision a few years ago to create a Global Supply Chain team, and I was thrilled to lead that as employee number one. Our early wins in logistics immediately fueled further investment in warehousing, inventory management and fleet operations. In 2024, we recognized the need to establish supply-chain excellence in a global setting. We grew our international trade expertise and expanded beyond the U.S. into key global markets (something that has set AVI-SPL up with an advantage within the chaos of tariffs and geopolitical volatility).

CI: Dive into the data-driven, constantly evolving process-improvement approach that the Global Supply Chain team embraces. How is this a reflection of the team members and the methodological background they embrace? And how does this bear fruit?

Codiroli: Those who study the historical Japanese mastery of process improvement quickly learn the term “kaizen,” stemming from the words “kai” (“change”) and “zen” (“good”). Overall, this represents continuous improvement. Prior to this role, I was leading many of AVI-SPL’s operations excellence initiatives with kaizen as the guiding principle. Our Global Supply Chain team has embraced that same kaizen mindset as the core of how we operate; with several Lean Six Sigma certifications from White Belt all the way up to Master Black Belt.

We never rely on gut feel — every choice is grounded in real‑time data and rigorous analysis. This uniquely positions our team to succeed in a world where macroeconomic variables are quickly being added, adjusted or removed. While other supply-chain teams are grappling to survive the constant change being forced on them by external forces, we embrace it and turn each obstacle into momentum used to create an even better future state.

CI: One unique differentiator of the Global Supply Chain team is how closely it works with the Sales department. How does this reflect the team’s signature customer-centricity, as distinguished from a purely internal-focused mindset?

Codiroli: Traditionally, supply-chain teams are inward-looking and operations-focused. I mentioned our Global Supply Chain team lives by the kaizen principle of continuous improvement. This improvement is not defined through the lens of our team but from the perspective of our customers. “Customer-Centric Kaizen” can only be achieved by partnering with both our sales team and customers to ensure every process maps to a customer need. This strategy is embraced from the top of our sales team by our Chief Revenue Officer, Dale Bottcher.

CI: Describe your hyper-localized strategy to E-waste, including how AVI-SPL’s team has built a network of authorized E-waste providers in each market, and how this directly addresses customer pain points you hear about.

Codiroli: One pain point we frequently heard from our customers was their need to sustainably and responsibly dispose of older electronics (“E-waste”). In true AVI-SPL fashion of solving our customers’ problems, we invested in the creation of a brand-new E-waste service offering utilizing what I like to call a “hyper-localized strategy”. This approach is much harder than simply “checking the box” because we carefully designed an entirely new global network of high-quality, accredited E-Waste partners that leverages our scale, overlays directly on our established supply chain network, focuses on the best partner(s) within each local market and allows us to provide this specialized service to our customers at a lower cost. We can even execute data destruction and erasure standards up to the levels set by the Department of Defense and National Institute of Standards and Technology.

Last year our Global Supply Chain team partnered with Kelly Bousman, our SVP of ESG and Sustainability, to organize a pilot across the U.S. that will be wrapping up soon and transition into a full product launch this summer. Stay tuned!

CI: My understanding is that the team centralized its processes, with all supply chain best practices now being made from one centralized source and being implemented globally. How does this affect process changes, customer experience and overall effectiveness?

Codiroli: In an industry in which centralized support is not common and local offices are often left to individually fight their own supply-chain battles, our Global Supply Chain team broke the mold by centralizing all supply chain functions and best practices (based on the Association of Supply Chain Management) and implementing them globally. The main impact is that we are able to roll out strategic or tactical changes in a way that’s faster, more effective and more standardized. Not only is this simply better for the business, but customers feel the impact as well as they get the same elevated delivery experience wherever their project is located. We just hired our first supply-chain manager for the EMEA market to lead and recreate our North America success, and we are about to lead an Import/Export Kaizen event with our LATAM Supply Chain Team (via iCAP) this month.

CI: How has the Global Supply Chain team moved beyond the “buzzword” of AI and found real-world, implementable solutions? Any specific use cases you’d like to share involving LLMs or any other AI technologies?

Codiroli: AVI-SPL as a whole has embraced the use of AI and created an AI Center of Excellence, which two Global Supply Chain team members are a part of. Specific to AI solutions that my team is implementing, we are rolling out a proprietary LLM we custom-created and trained with a sea of both internal and external data that will be able to chat with users to determine best international trade terms (Incoterms) based on acceptable risk tolerance, cost competitiveness by region, specific equipment involved, etc. It can even adjust recommendations based on AVI-SPL strengths and weaknesses by world region. We believe this is a first in the AV industry; moreover, we have not seen this anywhere in the supply chain market.

Another use case we’re building out is around demand planning. No human or spreadsheet could ever analyze the billions of data points associated with every customer’s demand as it relates to our vendors’ supply, but AI can. By better aligning supply and demand through a collaborative sales and operations planning strategy with our vendors, we can better meet our customers’ needs in a significantly more efficient and effective way.

CI: My understanding is that AVI-SPL is the only AV integrator to become an official member of the Department of Transportation’s FLOW program. Is that correct? And, if so, how does that help you get ahead of supply-chain disruptions and formulate plans before other integrators can?

Codiroli: That’s correct. We are the first and only AV integrator to become an official member of the Department of Transportation’s FLOW (Freight Logistics Optimization Works) program. This allows us to have access to exclusive upstream supply-chain data from the DOT, so we can forecast in real-time where there may be risk of supply disruption and pivot accordingly. By the time our competitors realize there’s a disruption and are alerting their customers, we’ve already executed mitigation plans weeks in advance.

CI: Describe the overall culture within the AVI-SPL Global Supply Chain team. What foundational values or principles underpin your day-to-day operations?

Codiroli: Apart from focusing on the values already stated (kaizen, customer centric, data driven, etc.), my team focuses on creating a culture where people don’t just tolerate pressure but thrive precisely because they feel the mission-critical nature of our work. Additionally, everyone is encouraged to think of “crazy” ideas and own the process of making those ideas come to life. A popular slogan within AVI-SPL is “Dare to Dream.” I see this phrase as a challenge and a promise — and one that perfectly sums up our team culture.

CI: Is there anything else you’d like to add?

Codiroli: Supply chain excellence is no longer a luxury — it’s the cost of entry. AVI-SPL’s Global Supply Chain team aims to push the limits of what an AV integrator has traditionally been able to accomplish. I mentioned the E-waste example, but another is what we’re doing with secure supply chain. We partnered with Mike Garvey, our SVP of Federal Sales and Operations, to expand our supply-chain partnerships, develop another layer on our global supply-chain network and create a new service offering in which we can transport AV equipment with the highest level of security. This includes secure chartered flights, tamper-evident seals, alarmed vehicles, GPS tracking/logging and chain of custody controls from start to finish (in nearly any country in the world).

We have built out the partnerships, processes and functionality to literally do military-grade logistics into active warzones. (We don’t, but that is truly the extent of our supply-chain capabilities now.)

There’s a reason AVI-SPL’s Global Supply Chain team has grown so rapidly: We listen to our customers and solve their problems in a way they didn’t know were possible. We’re not here to just get the job done — we’re building the most elite supply chain this industry has ever seen.